On August 1st 2024, the BMWK-funded research project FloatStructure officially started. Andreas supports ESOS Wind GmbH in the conceptual implementation of the project. It forms part of the collaborative research initiative FloatModular, which aims to develop new floating offshore wind turbine (FOWT) concepts based on a modular and scalable support structure adaptable to different water depths and turbine sizes.

about conmecs - continuum mechanics solutions

conmecs is an independent engineering company specialized in numerical flow analysis for maritime and offshore applications.

Founded by Andreas Brehm, the company combines applied research methods with practical engineering to deliver reliable and physically consistent CFD and FSI simulations.Its work focuses on hydrodynamic and fluid-structure interaction phenomena relevant to the performance and integrity of ships, appendages and offshore structures. In addition to engineering simulations, conmecs offers consulting in the interpretation of existing CFD results and in solving general flow-related engineering problems — supporting partners in identifying physical causes and assessing modelling consistency.How can I assist you?

Feel free to get in touch to discuss your current CFD or hydrodynamic case

recent projects

current research and industrial work involving CFD and FSI

BMWK-funded R&D project CableProtect started

Andreas supports ESOS Wind GmbH by taking over the CFD investigations in the BMWK-funded research project CableProtect, which started in September 2023.

CFD support in the BMWK-funded research project DigitShip (2022-2024)

In the years 2022-2024, Andreas supported the Institute for Sustainable and Autonomous Maritime Systems (INAM) at the University of Duisburg-Essen (UDE) in conducting CFD investigations for the BMWK-funded research project DigitShip.

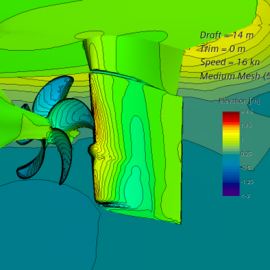

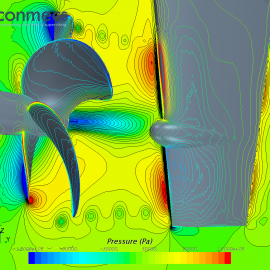

conmecs supports Siemens Energy in R&D project

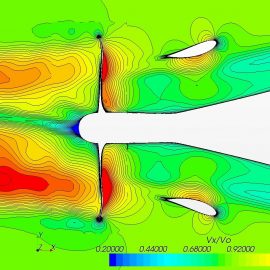

Siemens Energy Global GmbH & Co. KG is a leading global company that offers services for energy generation and transmission with a strong focus on renewable energies and solutions for the decarbonization of existing customer processes. Siemens Energy’s maritime division offers effective podded drives (PODs) for the shipping industry. Recently, Siemens Energy asked conmecs to support the CFD investigations in a R&D project.

approach & values

“Transparent, efficient and responsible — always focused on the client’s engineering goals.”

case studies

practical applications & concept analyses

rudder loads

The design of rudders are usually based on class society rules. The required, minimum rudder area is estimated in relation to the ship’s wetted lateral hull area. Rudder profiles come from old, successful shipbuilding projects. Rudder designs are often developed by another supplier, regardless of the propeller manufacturer. The positioning hull-propeller-rudder is traditionally based on experience from old projects.

smoke gas propagation

The exhaust emissions from ships are not only discussed in terms of GHG (greenhouse gas) reductions. The operators of offshore supply vessels (OSV) are concerned about their technical employees who work primarily on deck and are exposed to the exhaust. In addition to these health matters, yacht and cruise ship operators want to avoid that passengers be disrupted by the smell of exhaust gases.

energy saving devices (ESD)

There are a lot of different energy saving devices (ESD) on the market, e.g. pre-swirl fins, ducts (Schneekluth, Mewis), and post-swirl devices (costa bulbs, rudder fins and hub fins). The suppliers promise efficiency rates, which lie within achieved rates of former projects and the spread is often relatively high, e.g. savings of “2 up to 6%”. For ship owners it is difficult to decide, which device is the best solution for their particular ship design.

reefer cargo hold ventilation

About ten years ago the proper ventilation of perishable goods was an issue for some ship owners and operators. Many reefer cargo hold ventilation systems were designed with a weak performance and the cooling units of containers failed during transport due to intake temperatures above the cooling units maximum design temperature. This problem has been solved for many container ships due to the design of ventilation systems according to new regulations, which take into account conservative fresh air volume rates.

company news & insights

evolving towards a fully digital workflow

Since the pandemic, digital collaboration has fundamentally changed the way engineering and research projects are managed.

investment in independent High-Performance CFD capability

To strengthen its long-term numerical hydrodynamics capability, conmecs has invested in a permanent Siemens STAR-CCM+® PowerPlus license.